And if you’ve never used a sewing machine before, the thought of threading for the first time can seem scary. Sometimes it can put you off the task of sewing altogether.

However, learning to thread a sewing machine is not as hard as it seems, and with a little practice and perseverance, you’ll get the hang of it sooner or later.

Sewing machines are available in various sizes and models; however, the mechanism for making stitches on a home sewing machine remains the same.

The process simply involves making stitches by combining the needle to the second thread coming from the bobbin.

So how exactly do you thread a sewing machine? It’s easier than you think, and threading a sewing machine can be accomplished in a few simple steps.

The faceplate on any sewing machine is numbered with the steps that you need to follow in order to guide the thread through the machine. And all machines follow the same basic principle.

So all you need to learn is the basic steps to threading a sewing machine, and you’ll be on your way to creating your first piece of clothing.

Contents

Threading a Sewing Machine: Step by Step

Step 1

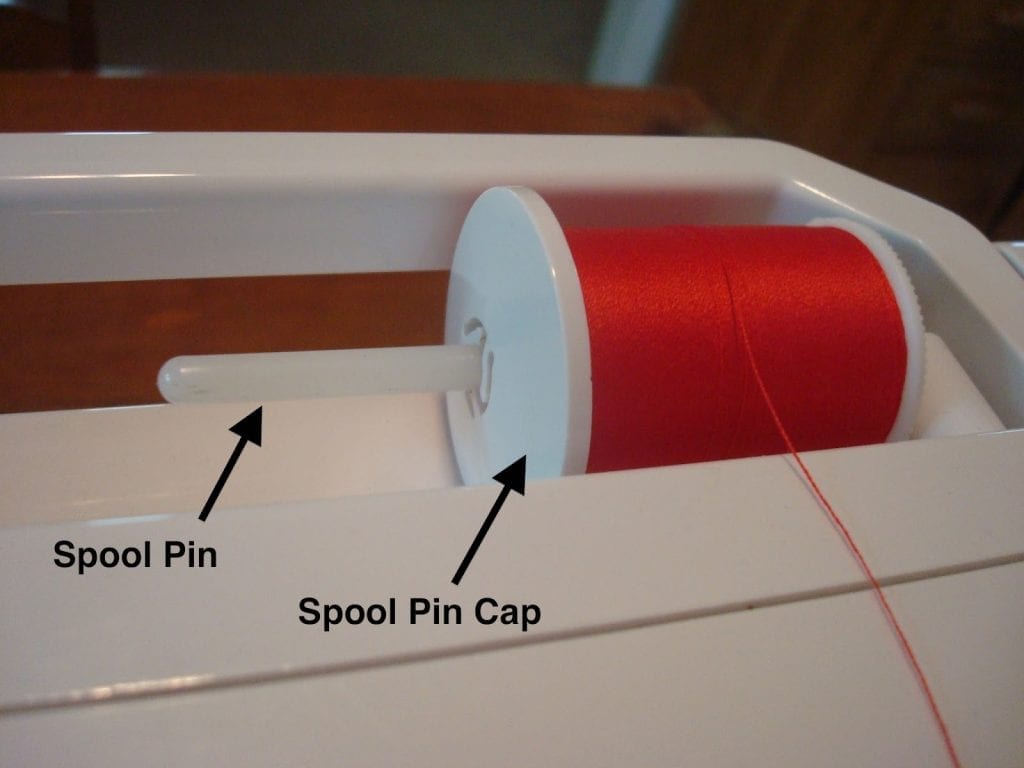

The first step threading a sewing machine is placing your thread spool on the spool pin.

The spool should be turned so that the thread is released counterclockwise.

While you’re doing this, check the top of your machine for the diagram before you place the thread spool.

Certain machines have a small diagram on top that guides you as to where the thread spool should be placed.

Step 2

In step two, you will need to pull the thread out.

You should tug at the thread in order to pull it out and then wind it on the winding tension disc, which is located at the top of the sewing machine.

You’ll find this spot on the opposite end of the sewing machine, and just above the needle. The discs might also have a small wire attached to it, which helps to hold it in place.

Step 3

Getting the bobbin is your third step.

Take the end of it and insert it through one of the holes in your bobbin. You should then wrap the thread around the bobbin a couple of times to secure it.

Bear in mind that they are also pre-threaded bobbins available in craft stores if you don’t particularly want to thread your own bobbins.

Step 4

In step four, you want to put the bobbin on the bobbin pin.

The bobbin is a small pin that is likely positioned on the top of your machine near where your spool is located.

Take the bobbin and place it on this pin. Thereafter slide the pin over to the right to lock the bobbin in place and prepare for winding.

In this process, you should hear the bobbin pin click so that you know it has been locked in place when you slide it over.

Step 5

Start winding the bobbin for a couple of seconds and then push the bobbin winding button.

After a few rotations, you can stop for a moment to cut off the excess thread that sticks out of the hole in the bobbin.

Step 6

Finish winding the bobbin in step six.

Gently apply pressure to the floor pedal once again. The winder should then be flipped back on to allow it to fill the bobbin with the thread completely.

When the bobbin is full, your winder will likely stop. However, if it doesn’t stop, you can stop it manually.

Step 7

In step seven, you should remove the bobbin and slide the bobbin pin over to the left.

The thread will be attached to both the spool and the bobbin.

So the excess should be cut off with a pair of scissors leaving a 2 to 3-inch tail.

When the bobbin is full, you can start to thread the machine.

Threading the Upper Half of the Machine

Step 1

In this first step of threading the upper half of the machine, you should locate the spool pin on the right side of the machine.

On the right-hand side, the spool pin will be the larger of the two pins placed on the side.

Place your thread onto the spool pin and then pull thread away from it. This spool pin may be more solid or more stable if you place it so that the thread is coming from under the spool when you are looking down on it.

If you have one of those machines that have a diagram on it, the diagram will make sure you know which direction it should be going.

Step 2

In the second step, you should wrap the thread around the guide.

Pull the end of that the thread out from the spool.

Then bring the thread across the top of the machine and through the thread guide, which is located on the top of the machine.

This will ultimately look like a silver piece that is sticking out from the top.

Then bring the thread out at the backside of the guide and towards the front of the U-shaped area. You are likely to see printed guidelines on top of the machine or diagrams showing you how to work the thread through this area.

Step 3

In the third step, you need to pull the thread down.

Follow the directional arrows on the sewing machine by pulling the threads through the guide and in your direction.

You should then loop it on the tension discs at the bottom and then back up towards the top along the second thread guide.

Ultimately you create a long narrow U-shaped with the thread.

Step 4

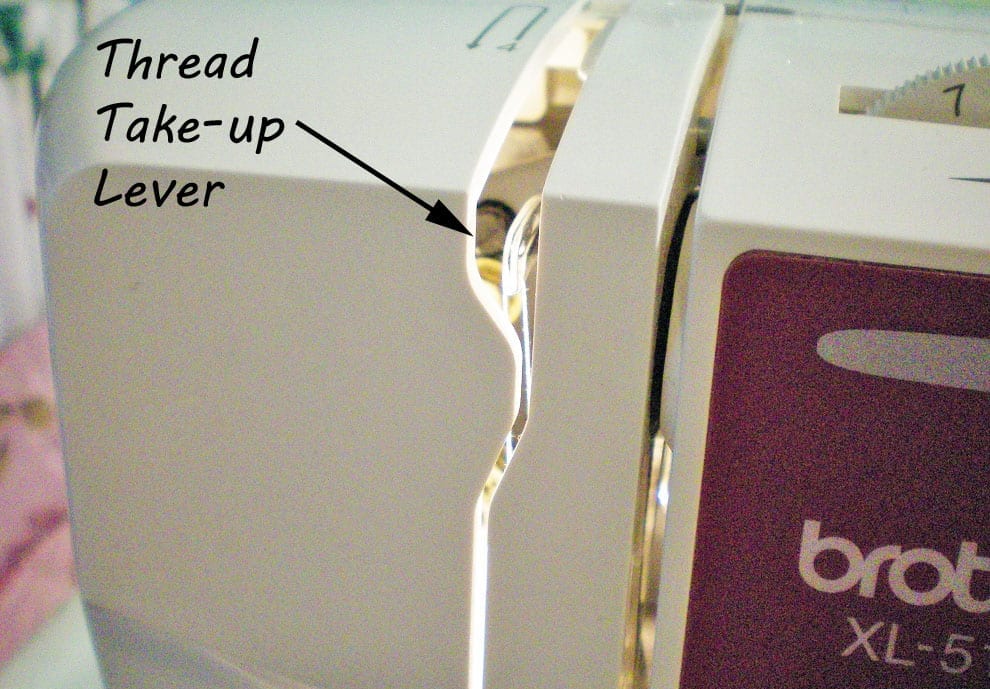

Warp the thread around the take-up lever in this fourth step.

After you’ve completed the U-shape, wind the thread around the top and then back down towards the needle.

If you are not sure of what the take-up lever is, then it simply a metal piece sticking out of the second thread guide.

This metal piece has a hole cut out near the top, and the thread needs to go through this hole. Complete this process, and it should create a narrow ” S” with the thread.

Step 5

Finally, thread the needle and pull the thread back down the machine towards the needle.

Thread the needle through the small eye and pull several inches out onto the other side.

Pull this thread through the gap in the small metal presser foot located underneath it. Your upper half of the machine is now threaded, and all that’s left to do is complete the lower half of the machine.

In this final step, all you need to do is remove the covering on the lower compartment and then unwind a few inches of the thread from the bobbin.

Then place the bobbin in the compartment below the needle and, lastly, expose the bobbin thread.

Related Questions

Can you find pre-threaded bobbins out there?

Yes, if you would like to skip this process, you may find pre-threaded bobbins in craft stores.

Can you learn how to thread a sewing machine overnight?

No, threading a sewing machine especially if you are completely new to it will take time, patience and lots of practice.

Are the different ways to thread a sewing machine?

While some steps may vary from one type of sewing machine to another, ultimately, threading mechanisms on all machines follow the same principle.